E. coli at Red Cow - A Primer On Handling Foodborne Illness In Your Operation

November 23, 2024 by Michelle Hill

The first report came into the Minnesota Department of Health (MDH) on November 2, 2024 – a customer of a local restaurant chain was sick with E. coli O157:H7 and the only place outside of home they had eaten at over the previous week was at Red Cow. With a big finger of blame clearly pointed at Red Cow, a dynamic, successful, build-your own burger joint with multiple locations throughout the Twin Cities Metro. Over the next week, 15 additional people were identified as part of this E. coli outbreak. It became quickly clear that the checks and balances of food safety had been violated at a significant point. The big mystery – where did safety fail and how can it be quickly corrected and food safety confidence restored?

As the folks at Red Cow know, a food operation cooking raw ground beef to customer specs must ensure active managerial control and maintain a strong Food Safety Culture in order to retain employees – nobody wants to work in an operation that makes customers sick – and to maintain a dedicated customer base – sick customers don’t come back.

What is Active Managerial Control?

According to the FDA Food Code Active Managerial Control (AMC) is defined as “the purposeful incorporation of specific actions or procedures by industry management into the operation of their business to attain control over foodborne illness risk factors.”

Transparency – the Only Response

Taking immediate action by offering complete transparency of your food safety practices and working hand in glove with the local regulatory authority is the only way to respond to a crisis of this magnitude. Demonstrating compassion and concern for the customers impacted by illness, communicating with the local regulatory authority immediately, openly, and honestly, and taking control of the story by interfacing with local media are necessary steps in recovering your reputation and regaining the public’s trust in you and your products.

Red Cow proactively issued a statement to local news outlet, KARE 11, taking control of the story by acknowledging the ill customers, disclosing they are working with the local health authorities – MDH and the Minnesota Department of Agriculture (MDA) – to identify the source of the contamination and that they have removed the product and supplier from their operations. They encourage people experiencing signs and symptoms of E. coli infection to seek medical attention.

What is E. Coli?

Image Credit: Creative Commons

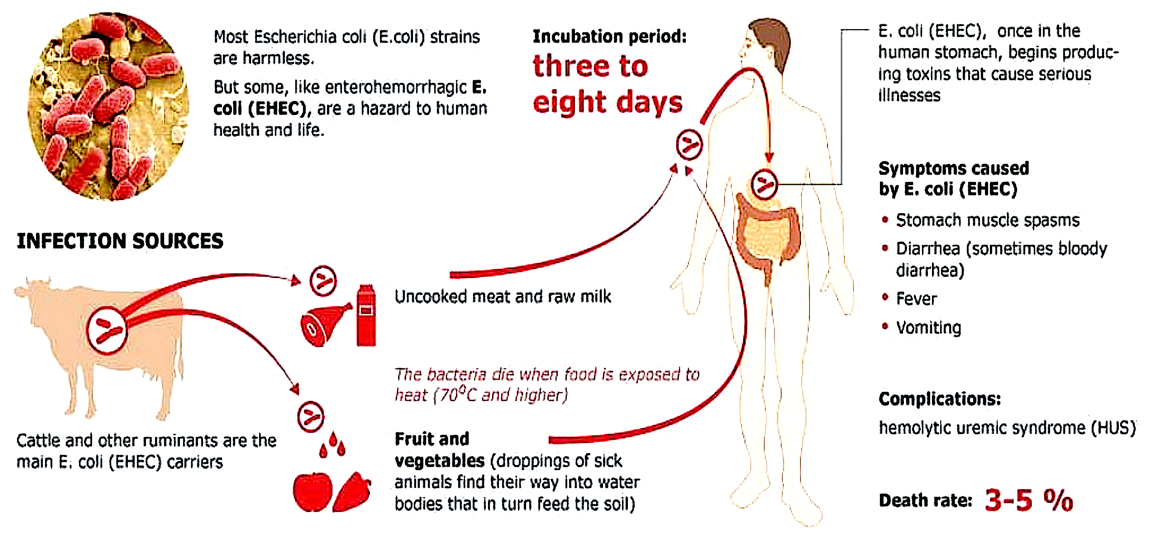

E. coli are bacteria found in many places, including the intestines of people and animals. The highly-infectious E. coli strain, O157:H7, is found only in the intestines of ruminant animals (such as Cows) and people infected with it. Human’s harboring this strain can suffer from diarrhea, urinary tract infections, pneumonia, sepsis, and most life-threatening of all, hemolytic uremic syndrome (HUS). HUS can lead to kidney failure, permanent health problems, and even death.

Signs & Symptoms of E. coli Infection

Image Credit: CDC

They also disclosed that 61 other restaurants in the Metro Area share their same supplier and have purchased the same ground beef product for use in their respective operations. They emphasize that they have suffered “No closures” and “…all of our locations have been thoroughly disinfected and sanitized following Department of Health standards to ensure our environment is safe for all our guests and team members.” All are necessary actions to be taken during an outbreak, but through the act of full disclosure, Red Cow has reassured the local community and has begun the potentially elusive process of regaining customers, especially those who have suffered illness.

Escalating Concerns – Declaring an Outbreak

Declaring a foodborne illness outbreak is a big deal – for the customer, the operation, and the regulatory authorities. Declaring an “outbreak” has legal implications and certain clear criteria must be met – including proof that two or more people are sick after having consumed from the same batch of food, an investigation is undertaken, and the necessary science is applied to prove the link between the ill people and the suspected source of contamination.

The Food Safety Partnership

MDH quickly partnered with the Minnesota Department of Agriculture (MDA) and together they reached out to FSIS (USDA’s Food Safety Inspection Service), getting the powerful Federal regulatory ball rolling. Per a press release issued recently, “FSIS was notified of illnesses on November 13, 2024, and working in conjunction with local authorities, FSIS determined that there was a link between the ground beef products from Wolverine Packing Co. and this illness cluster. On November 20, 2024, a ground beef sample collected by the Minnesota Department of Agriculture as part of an outbreak investigation tested positive for E. coli O157. To date, 15 case-patients have been identified in one state with illness onset dates ranging from November 2, 2024, to November 10, 2024. FSIS continues to work with the Minnesota Departments of Agriculture and Health on this investigation.”

Surveillance is Safety

Recognizing the potential severity of E. coli infection, and the death it may bring to some, taking corrective actions is obvious and necessary. By ensuring access to the necessary tools for rapid, accurate product testing and invoking the power of recalling a product from the marketplace, FSIS (the USDA’s Food Safety Inspection Service) is the food safety gatekeeper for Consumers in this country.

Before meat products enter the food supply, USDA-regulated slaughterhouses are required to follow strict protocols to screen for E. coli in their products as part of the Pathogen Reduction/Hazard Analysis and Critical Control Point (HACCP) system. This process includes preventive measures, testing, and monitoring to ensure the safety of meat products.

Stay up to date with all things Food Safety

Get HACCP Zone news and updates straight to your inbox.

USDA and HACCP – An Overview

Step 1. Ante-Mortem Inspection – USDA inspectors examine live animals for signs of illness, injury, or contamination that could introduce pathogens like E. coli into the meat supply. Animals showing signs of disease are removed from the slaughter process.

Step 2. Sanitary Dressing Procedures – Facilities implement sanitary dressing procedures to prevent contamination during slaughter and processing. Critical steps include: cleaning equipment and tools, removing visible contamination (e.g., fecal matter, hide dirt) from carcasses, and employing the use of antimicrobial sprays or steam pasteurization on carcasses prior to further processing.

Step 3. HACCP Plan Implementation, including:

Hazard Analysis: Slaughterhouses must identify potential sources of E. coli contamination, particularly at critical stages like evisceration, carcass splitting, and chilling.

Critical Control Points (CCPs): Facilities determine CCPs where interventions, such as temperature controls or antimicrobial treatments, reduce or eliminate E. coli contamination.

Preventive Measures: Facilities use interventions like steam pasteurization, hot water washes, or organic acid sprays (e.g., lactic acid) to kill pathogens on carcasses.

Step 4. Microbiological Testing for E. coli include:

Testing for Generic E. coli: General E. coli is used as an indicator organism to verify overall hygiene and process control. Testing involves taking carcass or product samples, swabbing them, and culturing for E. coli.

Testing for Shiga Toxin-Producing E. coli (STEC): USDA requires testing for pathogenic strains (e.g., E. coli O157:H7, O26, O45, O103, O111, O121, and O145) in raw beef products. Samples are tested using rapid methods like PCR (Polymerase Chain Reaction) or culture confirmation techniques.

Step 5. Sampling Procedures include:

Carcass Sampling: Swabs are taken at pre-determined points (e.g., after evisceration or chilling). Samples are tested in-house or sent to external laboratories.

Ground Beef Testing: Random samples of raw ground beef are collected to test for pathogenic E. coli.

Frequency: The frequency of sampling is determined by production volume, history of compliance, and specific regulatory guidelines.

Step 6. USDA Verification – The USDA’s Food Safety and Inspection Service (FSIS) conducts random, unannounced inspections and testing at slaughterhouses to verify compliance.FSIS tests samples for STEC and enforces mandatory recalls if contaminated products are identified.

Step 7. Corrective Actions – If E. coli contamination is detected, affected lots are withheld from commerce, and additional testing is conducted.Facilities must implement corrective actions to address the root cause, such as revising their HACCP plan or enhancing sanitary controls.

Step 8. Record Keeping – Facilities maintain detailed records of testing, monitoring, and corrective actions as part of their HACCP compliance. These records are subject to USDA inspection to verify adherence to regulatory requirements.

Identifying the Cause of Outbreak and Moving Forward

It is positive news for Red Cow that FSIS has identified ground beef supplier, Wolverine Packing Co., Detroit, Michigan, as the source of E. coli contamination. By actively following the principles of HACCP, Red Cow has shown through the act of transparency their operations strong commitment to Food Safety, and will quickly regain public trust which will encourage customers to return in force. After all, the safest place to eat is one that has been through this process because they will actively ensure it never happens again.

We can partner with you to ensure HACCP works for your operations – send us an email.

Further Reading

Minnesota Department of Health (MDH) Press Release, “E. coli O157 infections linked to consumption of burgers from Twin Cities restaurants”.

Food Safety News Article, “New E. coli outbreak associated with hamburgers from restaurants in Minnesota”.